eFree form

HOME > Product introduction > eFree form

-

Strength

eFree form, an eco-friendly paper form

Constructability free

- Installation free!

- You don't have to do any more the multiple work of using a heavy form or producing a square form and inserting a circular plastic pipe into it. Here is eFreeForm easy to install.

- From from movement!

- The eFreeform made light can be directly carried by workers during movement at sites.

- Free from dismantling!

- The eFreeform made of paper can be easily dismantled by a simple tool.

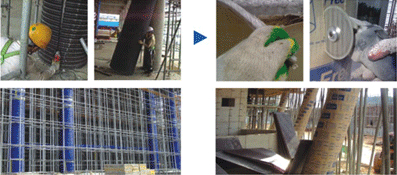

Long pillar also at once! Severely inclined pillar also simply!

eFreeForm can do it.

(Successful example of inclined pillars at single placing sites)

Economic efficiency free

- Labor cost, material cost and waste free!

- This realizes astonishing economic efficiency through reduction of labor cost, construction period and finishing cost by composing a superior site working condition in effective installation, easy movement and convenient dismantling. The eFreeform made of recycled paper is welcome to any site seeking economic efficiency with competitive material costs as well as eco-friendly materials without burden of waste. This enables easy and fast construction compared to the rental forms having to be stored and moved after dismantling and can be recycled as waste paper for raw materials of paper after use as a disposable form without burden of construction period depending on site conditions.

Selecting a beautiful and practical cylinder provides a broad view and an excellent space usability to give higher satisfaction to building users as well as building owners.

Environmental efficiency free

- Environmental level free!

- While the existing plastic forms are all wastes, the eFreeform can be recycled into waste paper as a raw material for making paper.

The eFreeform made of eco-friendly materials whose waste material can be used as a raw material again can reduce agony of constructors as well.

eFreeForm minimizes appearance problems like bends generated after dismantling of bellow forms to be free in beauty as well as save material and labor costs for protraction of additional finishing.

(Waste treatment after dismantling(environmental problem and cost generated), Waste paper recovery after dismantling(eco-friendly and economical), After dismantling of bellows, After dismantling of eFreeForm)

-

Purpose

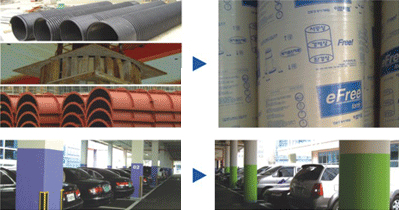

Mould for cylinder-shaped column of underground parking lot

As the design trend has transferred to round column for underground parking lot, it becomes common to choose efree form (eco-frielndly paper mould), given that it is one of the most economic and constructible materials. In addition, it can be a best possible alternative as it can be customized at production and come in many different standardized specifications, not requiring any additional in-site process for installation.

Installation example : Doosan We‘ve apartment complex in Sooncheon, Nexone apartment complex in Gumi, Cheomaeul apartment complex in Sejong, etc.

Mould for cylinder-shaped column of building

For the construction of main entrance or the lobby where large-scale circular column usually be designed, our eco-friendly paper mould maximizes constructability, economic efficiency and environmental friendliness as it is able to cast as a big column as 9 m once as a whole.

Installation example : Reconstruction of Hankook ilbo at Gwanghwamoon, Taean European Resort, Korea University Dormitory

Mould for cylinder-shaped column for subway station

Installation example : Soraepogu station in Incheon, Gyeongchun railway depot station, etc.

Cylinder-shaped mould for bridge of road

Eco-friendly paper that can be produced in up to 2000m displays a great constructability as it is possible to install and cast on the same day. It is the biggest difference from the existing mould that requires casting in several steps due to the high cost of form, leading to huge burden on the cost of pump car, crane and labor. It demonstrates excellent product quality even at huge scale construction site such as road building.

Installation example : Highway between Choongju-Eumsung, Sanjoo highway, Yangsan interstate way etc.

Cylinder-shaped mould of circular column of factory/ plant

Install ation example : Linde Korea plant at Giheung, Praxair Korea Osan plant,

Cylinder-shaped mould for support of solar energy facility

Solar energy facility also needs paper form. When installing solar energy facility, thousands of column support shall be installed at the same time. Under such circumstances, efree form is now selected as one of the most economic options to secure both constructability and environmental friendliness.

Installation example : Taean LG solar energy plant etc.

Cylinder-shaped mould for irregular building

Recently, irregular and round shape building become a new architectural trend. As a result, it is natural that tilted round column and round column faced with retaining wall are requently applied. In this case, paper mould is a best possible solution in terms of constructability.

Installation example : DDP, Twin Trio Office, Pan-Gyo Techno Valley etc.

Cylinder-shaped mould for Korean traditional housing (Hanok)

Buddhist temple, and traditional style building

When recreating traditional Hanok into concrete building by using strengths of Hanok, or expressing unique design of traditional style such as circular column of Buddhist temple or rafter, eco-friendly paper mould of efree form enhances both constructability and economic feasibility.

Installation example : Jin-Gak Buddhist Order Main hall, Chunbulsa, etc

-

Specification

It is possible to produce in special size other than the specification described above. It is also possible to process by length for bulk order.

| Inner diameter(mm) |

Outer diameter(mm) |

Thickness(mm) |

Length(mm) |

| 250 |

258 |

4 |

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

customized production possible

|

| 300 |

310 |

5 |

| 350 |

360 |

5 |

| 400 |

414 |

7 |

| 450 |

464 |

7 |

| 500 |

516 |

8 |

| 550 |

566 |

8 |

| 600 |

618 |

9 |

| 650 |

668 |

9 |

| 700 |

720 |

10 |

| 750 |

770 |

10 |

| 800 |

821 |

10.5 |

| 850 |

871 |

10.5 |

| 900 |

921 |

10.5 |

| 950 |

971 |

10.5 |

| 1000 |

1022 |

11 |

| 1050 |

1072 |

11 |

| 1100 |

1122 |

11 |

| 1200 |

1222 |

11 |

| 1300 |

1322 |

11 |

| 1400 |

1422 |

11 (high-strength) |

3,000

4,000

5,000

6,000

customized production possible

|

| 1500 |

1522 |

| 1600 |

1622 |

| 1800 |

1822 |

| 2000 |

2022 |

| 2200 |

2222 |

-

Installation method

Bottom fix installation

-

- Select one from 4 installation cases shown in the pictures.

- If the column length is 4m or longer or lateral pressure of bottom concrete is expected high, ② or ③ is recommended.

The installation would be safer if it is supported with square bar.

Top area installation

-

- "It hangs beam over mould.”

-

- ① Hold the square bar to column

- ② flange work (round shape)

- ③ flange work (square sitting cushion shape)

- ④ hang the beam: if beam is supported against concrete casting, it does not compromise the bearing capacity of column mould load.

Verticality alignment

-

- It is good enough to support the upper correction area.

-

- ① Place support over riased spot of square bar (for hanging stand-alone column over beam)

- ② Direct support with stiffener (bottom support reinforcement for wide column consecutive casting)

- ③ Hold stand-alone column to prevent mould from escaping due to buoyancy (turnbuckle or other accessories)

- ④ Detail view of upper side of stand-alone column (how to fix with support)

Casting

-

- Start vibrator work from hoop inside.

- Please pay attention to 4/5 of the column from the bottom as it receives most lateral pressure. The finished surface would be cleaner and smoother if bubbles are raised by vibration.

Démontage

-

- Dismantlement

- It is easiest to dismantle 24-48 hours from casting.

With dismantling tool whose depth is adjustable, you can dismantle it without making any flaw.

Picture of beams connection

-

- If the construction requires to connect directly to column without beam, efree form is able to make frame easily.

-

- (1) Apply tape after processing the connection area according to the drawing

- (2) Support the processed area with square bar to reinforce the lateral pressure

- (3) Process the column connection area of beam form into round shape

- (4) Connect them not to be separated from the column

- (5) Dismantle after casting in order to complete clean connected column

- Installation case of consecutive casting“How to install the form of 10 m column at once”For wide column, you can install the column form at once using efree form connection socket.Method : Iron banding in a way to embrace the joint area with a provided socket with wooden square bar used as a support※ Socket for consecutive casting is provided for free.

Installation of wall connection

-

- For round column connected to the wall

-

- ① Locate the mould at the right position according to the drawing and process them with round saw.

- ② Finish cut area with tape after processing

- ③ Support the processed form with form or square bar to reinforce the lateral pressure

- ④ Fix the mould with external reinforcement material and nail from inside to avoid from mould escaping during casting.

Installation of wall connection

-

- For round column connected to the wall

-

- ① Locate the mould at the right position according to the drawing and process them with round saw.

- ② Finish cut area with tape after processing.

- ③ Support the processed form with form or square bar to reinforce the lateral pressure.

- ④ Fix the mould with external reinforcement material and nail from inside to avoid from mould escaping during casting.

Installation of tiled column

-

- It is possible to install tilted column by reinforcing the mould with square bar.

What to do in the following case?

-

- If heavy rain is expected right after installation: do reinforcement work while the protective vinyl remain covered.

- If it is wet: dismantle and cover it with residual material before doing reinforcement work.

- If water remains inside the form: create discharge outlet at the bottom then reinforce the outlet.

- If multiple number of beams are connected: reinforce with square bar after processing the connection area.

Please pay extra care for the following cases

-

- During on-site processing.

- be careful when taping the processed surface.

- be mindful of bottom shock during form installation, and be careful not to leave scratches inside the reinforced bar during form insertion.

- When storing them on-site, it shall be stored in 3 or lower layers.

- Be careful not to have water welled inside.

Disposal of waste

-

- Saving them saves you money.

- The residual material from the construction site is recyclable resource that would be bought by the junk shop for fee. It is eco-friendly material that does not cost you the waste disposal fee, but rather helps to promote morale of the workers.

- Use them as a container of consumable

- It is fine to use efree form as a container to store consumables on site. It can be used effectively as a container of consumables that are about the construction site and difficult to manage.